In the world of eyewear, the art of creating metal frames is a fascinating blend of design, engineering, and technology. For those curious about how these stylish and essential accessories are made, let's dive into the world of metal glasses frame manufacturing. The process is a symphony of precision, where advanced machinery and meticulous craftsmanship come together.

The Heart of Manufacturing: Key Automated Equipment

1. 3D Eyeglass Frame Bending Machine (or Auto 3D Eye Rim Bending Machine):

The journey begins with the Auto 3D Eye Rim Bending Machine. This state-of-the-art device is responsible for giving shape to the metal frames. It skillfully bends metal into intricate designs and precise shapes, ensuring each frame meets specific aesthetic and functional requirements. The machine's 3D capabilities allow for complex curves and angles, bringing the designer's vision to life.

Auto 3D Eye Rim Bending Machine

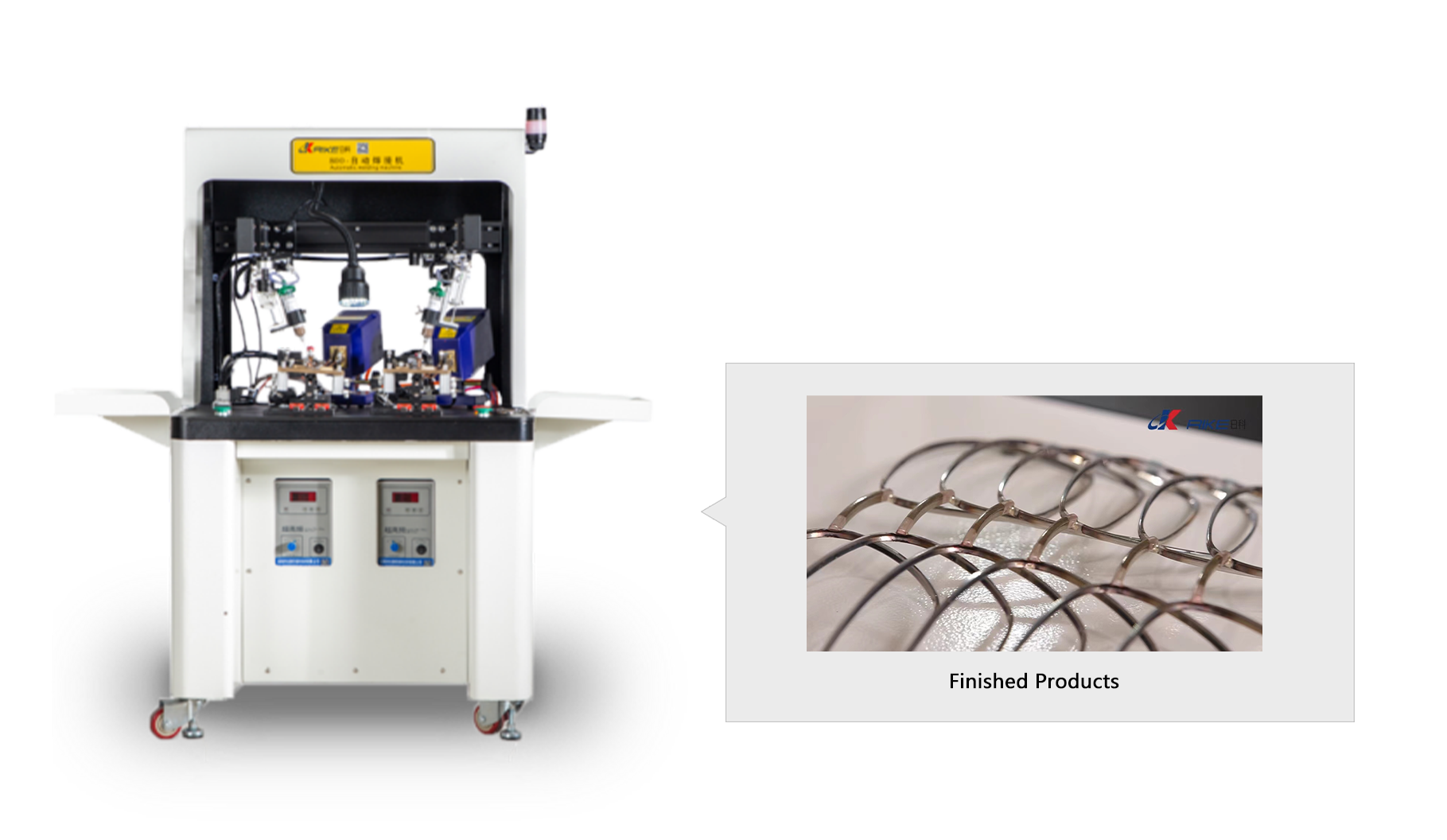

2. Automatic Eyeglass Bridge Welding Machine:

The nose bridge, a key comfort point on any pair of glasses, is crafted using an Automatic Welding Machine. This machine ensures a seamless and strong weld at the nose bridge, a part that often bears the brunt of daily wear and tear. The precision of this machine is crucial for both the durability and the comfort of the glasses.

Automatic Eyeglass Bridge Welding Machine

3. Automatic Eyeglass Hinge Welding Machine:

Last but not least, the hinges - the unsung heroes of eyeglass frames. Another Automatic Welding Machine takes charge here, focusing on the hinges that connect the temples to the front frame. The precision welding ensures the smooth operation of opening and closing the arms, a small but critical detail in the overall functionality of the glasses.

Automatic Eyeglass Hinge Welding Machine

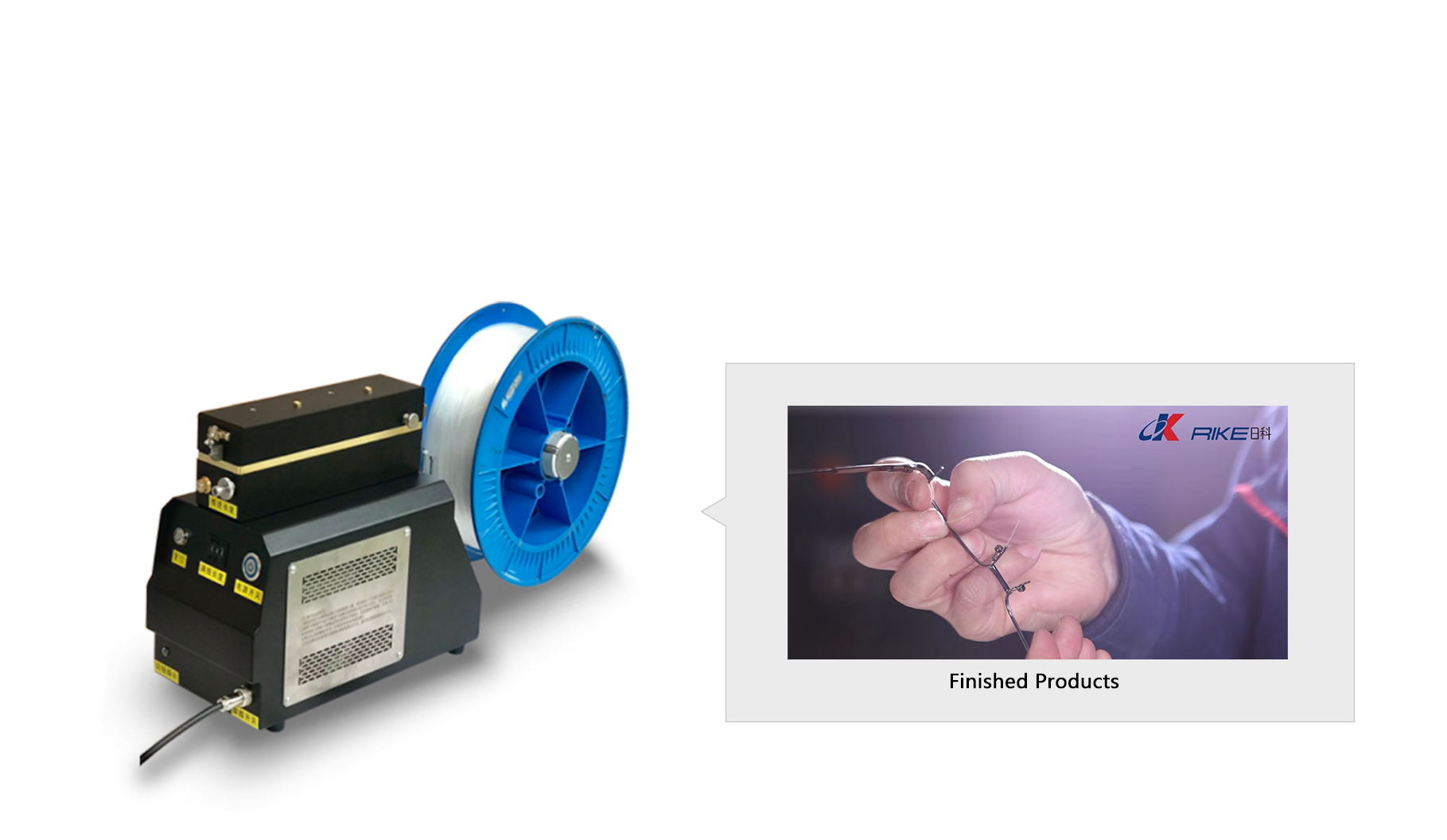

4. Eyewear Frame Threading Machine:

Next up is the Threading Machine, a game-changer in the production line. This equipment plays a crucial role in inserting wire into semi-rim frames. It's a leap from traditional manual threading, offering a high degree of accuracy and consistency. You can set the desired wire length and adjust the insertion depth, which results in a remarkable output of up to 500 pieces per hour - a significant boost compared to manual methods.

Eyewear Frame Threading Machine

Conclusion:

The manufacturing of metal glasses frames is a perfect example of how automation and technology have revolutionized traditional craftsmanship. These four key pieces of automated equipment - the Auto 3D Eye Rim Bending Machine, Threading Machine, and the Automatic Welding Machines for the nose bridge and hinges - are pivotal in transforming raw materials into the stylish and functional eyewear we use daily. They ensure efficiency, consistency, and quality in every frame produced, representing the pinnacle of modern eyewear manufacturing technology.

The next time you pick up a pair of metal frame glasses, take a moment to appreciate the intricate process and advanced technology that went into crafting this everyday essential.