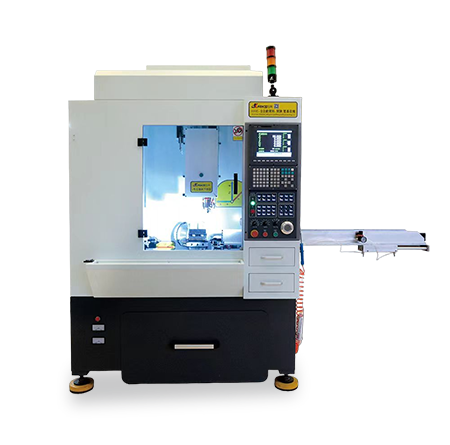

This machine is a dual-channel five-axis CNC milling machine capable of synchronous processing of inner and outer contours. The processing speed is approximately 90-180 seconds per piece. The machine consists of 11-12 axes and is equipped with 11-12 sets of Yaskawa servo motors from Japan. All main axes are driven by motors, lead screws, and guide rails, ensuring safety and stability. It is equipped with a high-speed automatic tool changer for efficient and safe tool change. The machine has a tool reserve of 3 tools for inner contour and 12 tools for outer contour, allowing a total of 15 tools to be used. It can complete any complex design in a single operation.

The machine features automatic feeding and simultaneous inner contour processing, saving time on outer contour processing. It has automatic tool change functionality for outer contour processing, allowing for synchronized tool change. The five-axis capability includes automatic flipping. It also has automatic material collection functionality, reducing manual material handling and preventing material loss.

| Model | RIKE 990C-II |

| Processing speed | 90-180s/pcs |

| Staffing | Auto Loading |

| Size(L*W*H) | 1700*2050*2200 |

| Weight | 2000KG |

| Voltage | 220V |

| Power | 4.5KW |

Device Information

The RIKE 990C-II models are Double Channel 5 Axis Acetate CNC Machines known for their advanced capabilities. With a processing speed of 90-180 seconds per piece, these machines offer efficient and precise operations. Their size of 1900*1800*2400 and weight of 1800KG indicate their robustness and suitability for industrial use. Operating on 220V voltage with a power requirement of 4.5KW.

| ACETATE EYEGLASSES |

|---|

| No | Product | Machine picture | Finished Products | Model | Processing Speed | Staffing | Size | Weight | Voltage | Power |

| 1 | Fully Automatic Dual Station Cutting Machine |  |  | RIKE 900-Ⅱ | 12 s/pcs | Auto Loading | 2500*1200*2000 | 1800KG | 220V | 4.5KW |

| 2 | Full automatic cutting, cutting, planing and pressing nose bridge machine |  |  | RIKE 990E | 25-30s/pcs | Auto Loading | 700*1600*2400 | 1800KG | 380V | 4.5KW |

| 3 | Automation planning Machine |  |  | RIKE 990D-Ⅱ | 20 s/pcs | Auto Loading | 1150*1200*2050 | 800KG | 380V | 2.0KW |

| 4 | Vacuum Baking Machine (25KW) |  |  | RIKE 25KW | 45min/650-700 pcs | 1 operator | 1800*2100*2300 | 1800KG | 380V | 35KW |

| 5 | Auto Nose Bending Machine |  |  | RIKE 780 | 10 s/pcs | Auto Loading | 850*1100*1800 | 800KG | 380V | 2.5KW |

| 5 | Auto Friction Bonding Machine |  |  | RIKE 280B | 14-38 s/pcs included loading time | Auto Loading | 850*1100*1800 | 700KG | 380V | 3.0KW |

| 6 | Auto 5Axis Intelligent CNC |  |  | RIKE 990C | 80-150 s/pcs | Auto Loading | 1700*1600*2400 | 1800KG | 220V | 4.0KW |

| 7 | Four station intelligent splicing machine |  |  | RIKE 270 | 45-60pcs/H | 1 operator | 1100*900*2000 | 1200KG | 380V | 4.5KW |

| 8 | Double Channel 5 Axis Acetate CNC Machine |  |  | RIKE 990C-Ⅱ | 90-180s/pcs | Auto Loading | 1700*2050*2200 | 2000KG | 220V | 4.5KW |

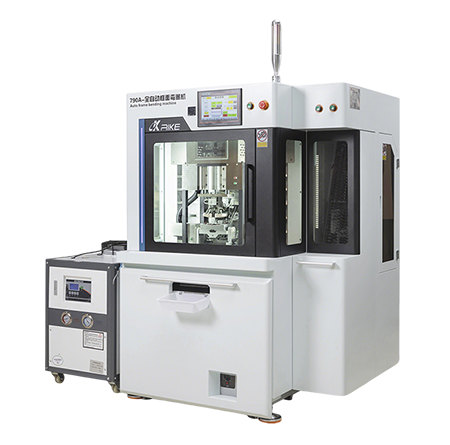

| 9 | Auto Frame Bending Machine |  |  | RIKE 790A | 15-20 s/pcs | Auto Loading | 1350*1250*1800 | 800KG | 220V | 2.5KW |

| 10 | Auto Hinge Insert Intelligent machine |  |  | RIKE 860 | RIKE 860 | Auto Loading | 1350*1380*1220 | 500KG | 220V | 2.05W |

| 11 | Automatic Cutting Temple and Planning Machine |  |  | RIKE 990E-Ⅱ | 20-40 s/pcs | Auto Loading | 1700*1600*2400 | 1800KG | 220V | 4.5KW |

| 12 | Automatic wire shooting Machine |  |  | RIKE 720A | 180 pcs/h | Auto Loading | 1320*1200*2200 | 1500KG | 220V | 3.0KW |

| 13 | 3 axis precision carving machine |  |  | RIKE 990F | 1 operator | 1400*1450*2000 | 900KG | 220V | 3.0KW | |

| 14 | 4 axis precision carving machine |  |  | RIKE 990F | 1 operator | 1400*1450*2000 | 900KG | 220V | 3.0KW | |

| 15 | Four axis high gloss machine |  |  | RIKE 990F | 1 operator | 1400*1450*2000 | 900KG | 220V | 3.0KW |