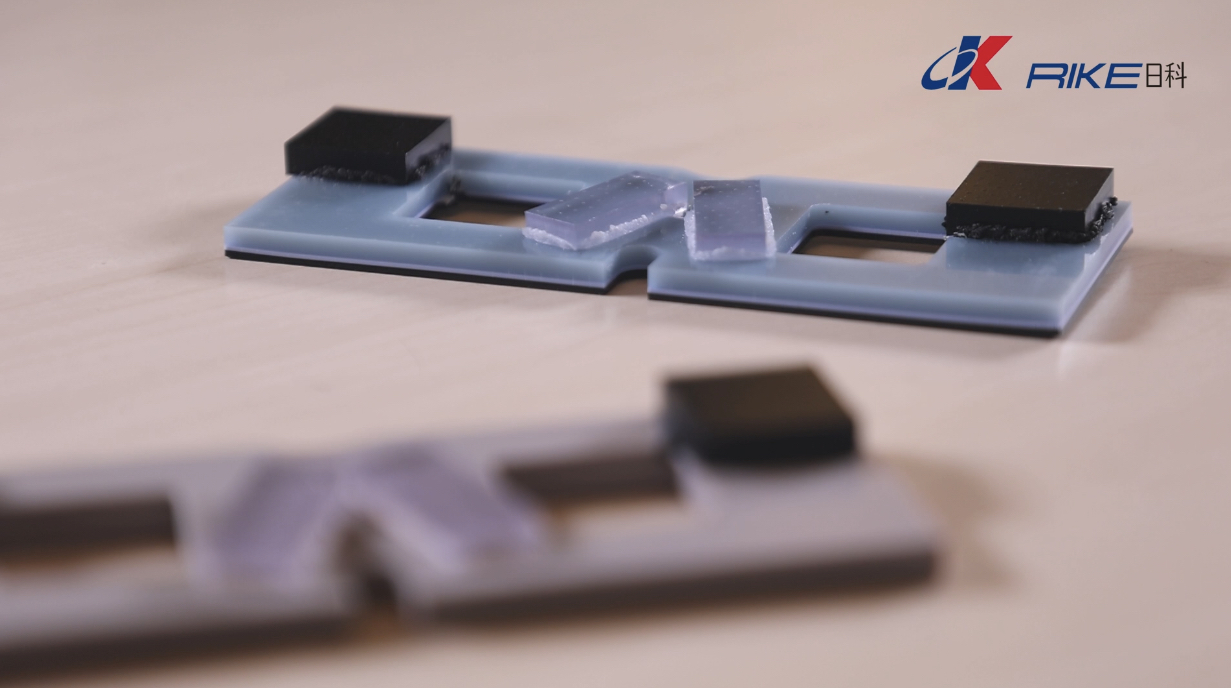

Through relentless efforts, RIKE has once again solved the long-standing technical bottleneck of low production capacity and difficult setup in the pin insertion process for eyewear manufacturing.

This machine replaces the traditional bead cage with our latest patented needle guide heating platform. The addition of high-frequency heating and preheating functions ensures a more stable surface temperature of the products. The processing time is approximately 18 seconds per unit, setting a new benchmark in processing precision that traditional bead cages cannot achieve. It represents a major breakthrough in this field.

The mechanical structure and other details of the machine are optimized with a design that enables extremely convenient and fast setup. The setup time for mold changeover is only 15 minutes. It features an adaptive function for copper needles, eliminating the need for adjustments when using different specifications of copper needles.

The team at RIKE has created this equipment with high precision and stringent requirements, which plays a decisive role in achieving the accuracy and consistency demanded by the processed products. It ensures stability without looseness or deviation during operation, allowing one person to manage multiple devices efficiently, even for small production batches. It fully demonstrates our deep and far-reaching considerations for the users' needs.

This machine is a user-friendly, efficient, and energy-saving fully automatic intelligent pin insertion machine, setting a new standard for future industry equipment.

| Model | RIKE 720A |

| Processing speed | 180pcs/h |

| Staffing | Auto Loading |

| Size(L*W*H) | 1320*1200*2200 |

| Weight | 1500KG |

| Voltage | 220V |

| Power | 3.0KW |

Device Information

The RIKE 720A Automatic Wire Shooting Machine is a powerful and efficient device designed for wire shooting operations. The processing speed of each product is 180 pieces per hour, it offers fast and precise performance. The machine's size of 1320*1200*2200 and weight of 1500KG ensure stability and durability, making it suitable for industrial use. Operating on 220V voltage with a power requirement of 3.0KW.

| ACETATE EYEGLASSES |

|---|

| No | Product | Machine picture | Finished Products | Model | Processing Speed | Staffing | Size | Weight | Voltage | Power |

| 1 | Fully Automatic Dual Station Cutting Machine |  |  | RIKE 900-Ⅱ | 12 s/pcs | Auto Loading | 2500*1200*2000 | 1800KG | 220V | 4.5KW |

| 2 | Full automatic cutting, cutting, planing and pressing nose bridge machine |  |  | RIKE 990E | 25-30s/pcs | Auto Loading | 700*1600*2400 | 1800KG | 380V | 4.5KW |

| 3 | Automation planning Machine |  |  | RIKE 990D-Ⅱ | 20 s/pcs | Auto Loading | 1150*1200*2050 | 800KG | 380V | 2.0KW |

| 4 | Vacuum Baking Machine (25KW) |  |  | RIKE 25KW | 45min/650-700 pcs | 1 operator | 1800*2100*2300 | 1800KG | 380V | 35KW |

| 5 | Auto Nose Bending Machine |  |  | RIKE 780 | 10 s/pcs | Auto Loading | 850*1100*1800 | 800KG | 380V | 2.5KW |

| 5 | Auto Friction Bonding Machine |  |  | RIKE 280B | 14-38 s/pcs included loading time | Auto Loading | 850*1100*1800 | 700KG | 380V | 3.0KW |

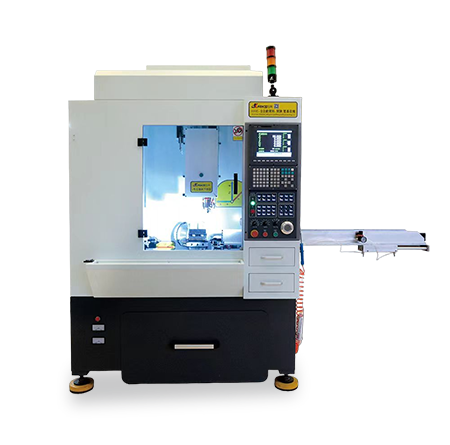

| 6 | Auto 5Axis Intelligent CNC |  |  | RIKE 990C | 80-150 s/pcs | Auto Loading | 1700*1600*2400 | 1800KG | 220V | 4.0KW |

| 7 | Four station intelligent splicing machine |  |  | RIKE 270 | 45-60pcs/H | 1 operator | 1100*900*2000 | 1200KG | 380V | 4.5KW |

| 8 | Double Channel 5 Axis Acetate CNC Machine |  |  | RIKE 990C-Ⅱ | 90-180s/pcs | Auto Loading | 1700*2050*2200 | 2000KG | 220V | 4.5KW |

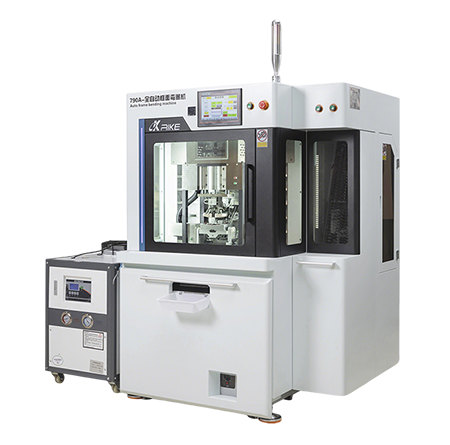

| 9 | Auto Frame Bending Machine |  |  | RIKE 790A | 15-20 s/pcs | Auto Loading | 1350*1250*1800 | 800KG | 220V | 2.5KW |

| 10 | Auto Hinge Insert Intelligent machine |  |  | RIKE 860 | RIKE 860 | Auto Loading | 1350*1380*1220 | 500KG | 220V | 2.05W |

| 11 | Automatic Cutting Temple and Planning Machine |  |  | RIKE 990E-Ⅱ | 20-40 s/pcs | Auto Loading | 1700*1600*2400 | 1800KG | 220V | 4.5KW |

| 12 | Automatic wire shooting Machine |  |  | RIKE 720A | 180 pcs/h | Auto Loading | 1320*1200*2200 | 1500KG | 220V | 3.0KW |

| 13 | 3 axis precision carving machine |  |  | RIKE 990F | 1 operator | 1400*1450*2000 | 900KG | 220V | 3.0KW | |

| 14 | 4 axis precision carving machine |  |  | RIKE 990F | 1 operator | 1400*1450*2000 | 900KG | 220V | 3.0KW | |

| 15 | Four axis high gloss machine |  |  | RIKE 990F | 1 operator | 1400*1450*2000 | 900KG | 220V | 3.0KW |