Creating glasses frames, whether they are made from acetate or metal, or whether they are sunglasses, reading glasses, or optical eyewear, is a complex process that requires precision and efficiency. With technological advancements, the eyewear manufacturing industry has transitioned from traditional handmade methods to fully automated production lines. Automation machines now play a vital role in crafting high-quality frames, significantly reducing the need for manual intervention. This article delves into the advanced processes and technologies involved in producing acetate and metal eyewear frames through automation.

● Acetate Sheet Cutting

● Process: The production starts with a dual-station cutting machine that uses synchronized cutting techniques to optimize material usage. This machine calculates the most efficient cutting plan, minimizing waste by precisely cutting the acetate sheets based on input dimensions.

● Molecular Reshaping of Acetate Sheets by Heating: Enhanced hardness and reduced deformation

● Process: After cutting, the acetate sheets undergo vacuum baking. This process uniformly heats the material using optical energy, reshaping the molecular structure to enhance hardness and reduce deformation. The machine can bake up to 1,200 pieces per cycle, significantly improving durability and consistency.

● Acetate Sheet CNC Planing: Precision surface refinement without water

● Process: The CNC planing machine refines the surface quality of the acetate sheets, achieving precise thicknesses without the need for water. Automatic feeding and discharge further improve surface finish, reducing the need for extensive sanding and polishing.

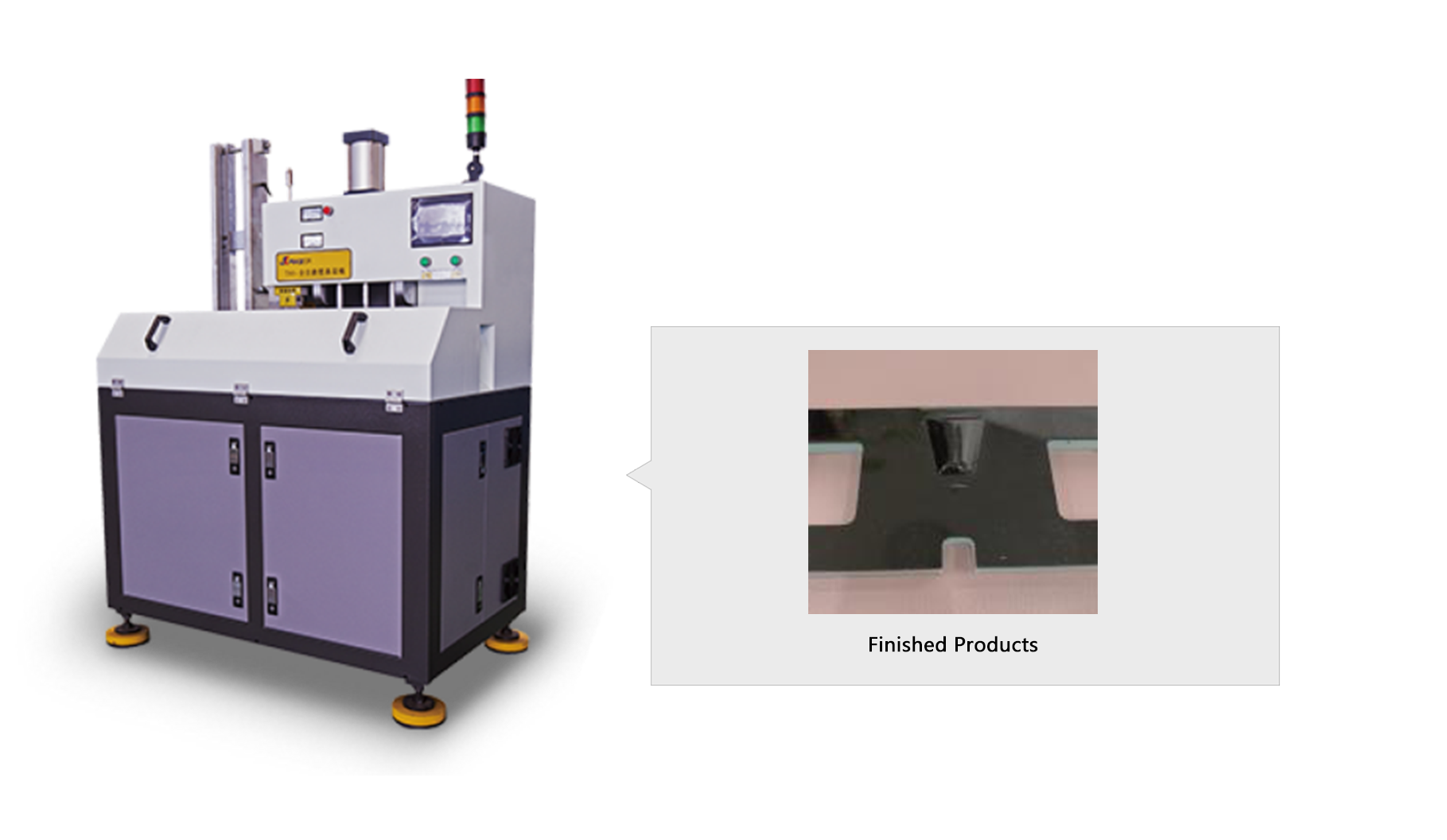

● Nose Bridge Bending: Automated bending, heating, and pressing of the nose bridge

● Process: The nose bridge of the eyewear is formed using an automated bending machine that performs simultaneous feeding, heating, and pressing. This ensures consistent dimensions and high-speed production, processing one piece every 10 seconds.

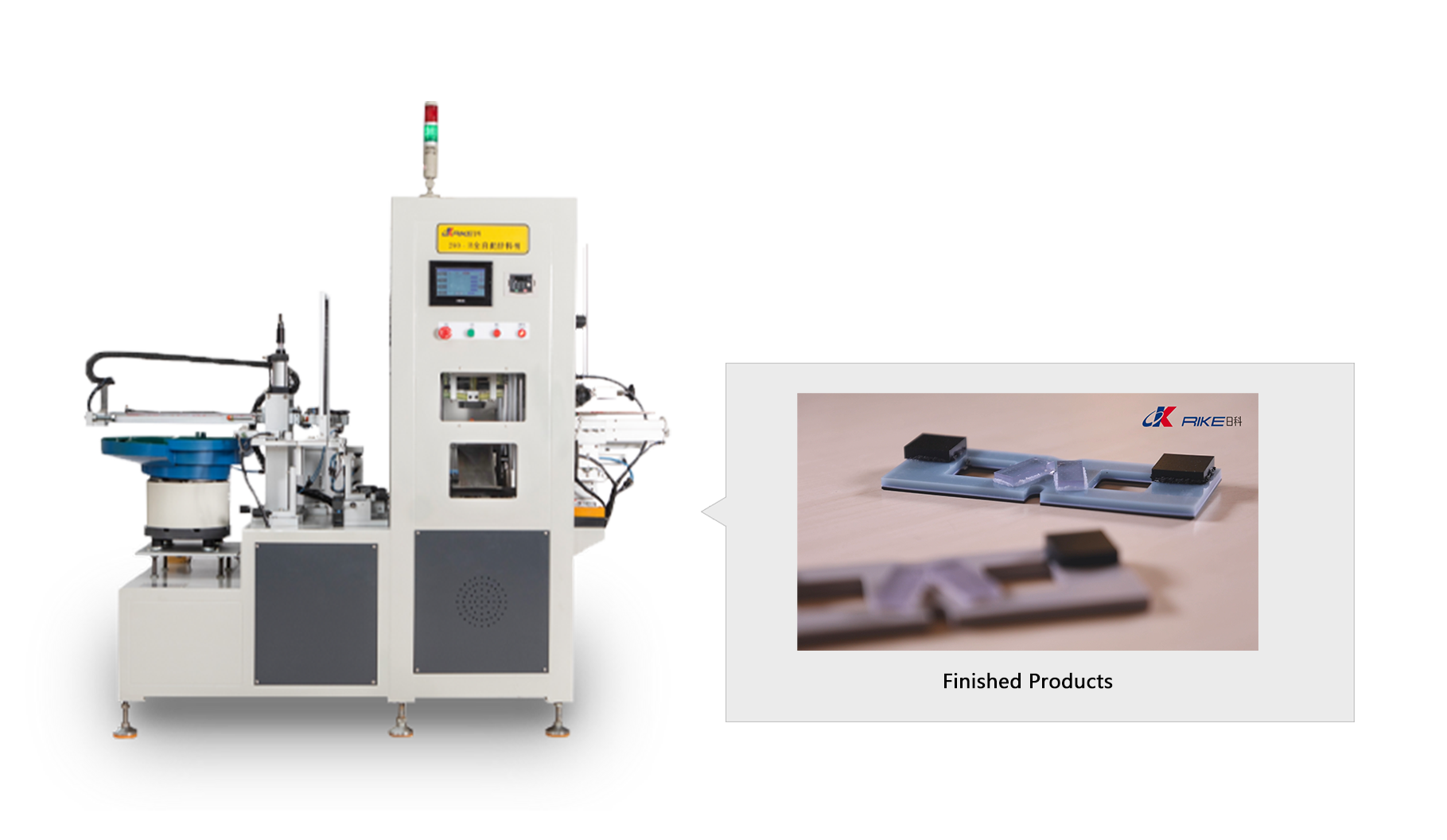

● Friction Bonding: Vibration friction splicing for joining acetate pieces

● Process: This machine uses vibration friction splicing to join acetate pieces. It can splice multiple pieces simultaneously or individually, ensuring strong bonds without defects. The process is completed in 14-38 seconds per piece, with automatic feeding enhancing efficiency.

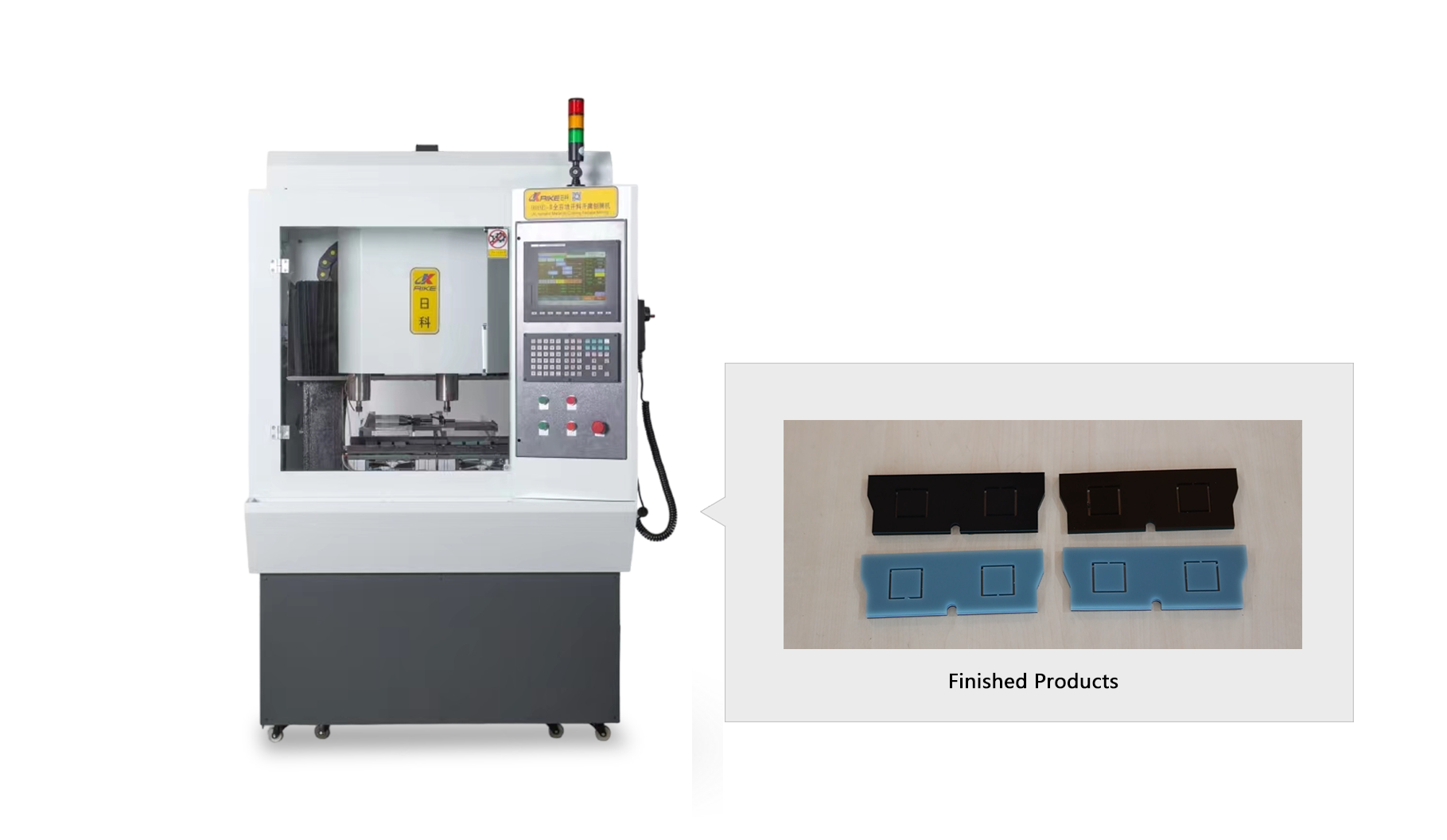

● CNC Shaping: Simultaneous inner and outer contour shaping

● Process: This advanced CNC milling machine shapes both the inner and outer contours of the frames. Equipped with dual channels and multiple servo motors, it can complete complex designs in 50-80 seconds per piece.

● Hinge Insertion: Automated loading, positioning, and nailing of hinges

● Process: Hinges are inserted using a machine that integrates automatic loading, CCD image positioning, height measurement, and hinge nailing. The machine ensures precision and operates at a speed of 35-40 seconds per pair.

● Frame Bending: Complete bending and shaping process with quick mold changes

● Process: This machine handles the entire frame bending process, from feeding and baking to bending and freezing. It ensures consistent quality with quick mold changes and precise temperature control.

● Temple Processing: Cutting, trimming, chamfering, and milling of temple parts

● Process: This machine combines cutting, trimming, chamfering, and milling in one operation, reducing processing time while ensuring smooth edges and accurate dimensions.

● Wire Shooting: Insertion of copper wires with high-frequency heating

● Process: The final step involves inserting copper wires into the frames using a high-frequency heating process. This machine operates quickly, completing each unit in about 18 seconds, and allows for easy adaptation to different wire specifications.

● Eye Rim Bending

● Process: This machine bends metal eyewear rims into precise 3D shapes, crucial for securely fitting lenses. It is versatile and maintains high precision across various designs and metals.

● Nose Bridge Welding: Automated welding with advanced agent for stability

● Process: This machine welds the nose bridge using a newly developed welding agent, enhancing product stability. It can weld various metals, including white brass, stainless steel, and manganese.

Dual-Station Nose Bridge Welding Machine: The machine features a dual-station rotary table that allows for simultaneous loading and welding, increasing production capacity by 1.5 times compared to traditional methods.

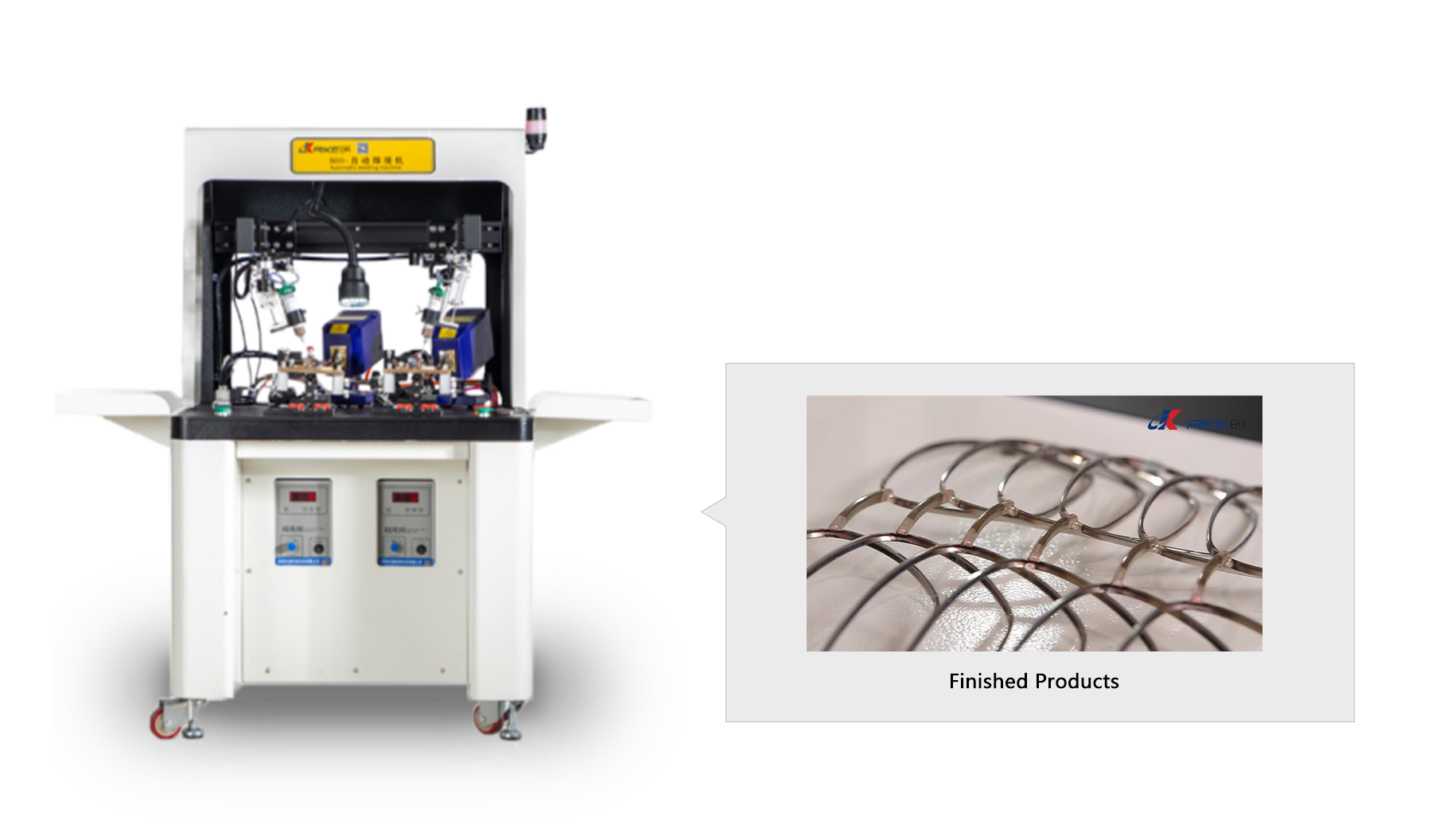

● Hinge Welding: Automated welding of hinges with high efficiency

● Process: This machine welds hinges and other parts of the eyewear frame using the same advanced welding agent as the nose bridge machine. It is designed for high efficiency and product stability.

Dual-Station Hinge and Temple Tip Welding Machine: This platform allows synchronized processing of hinges and temple tips, improving efficiency and ease of operation.

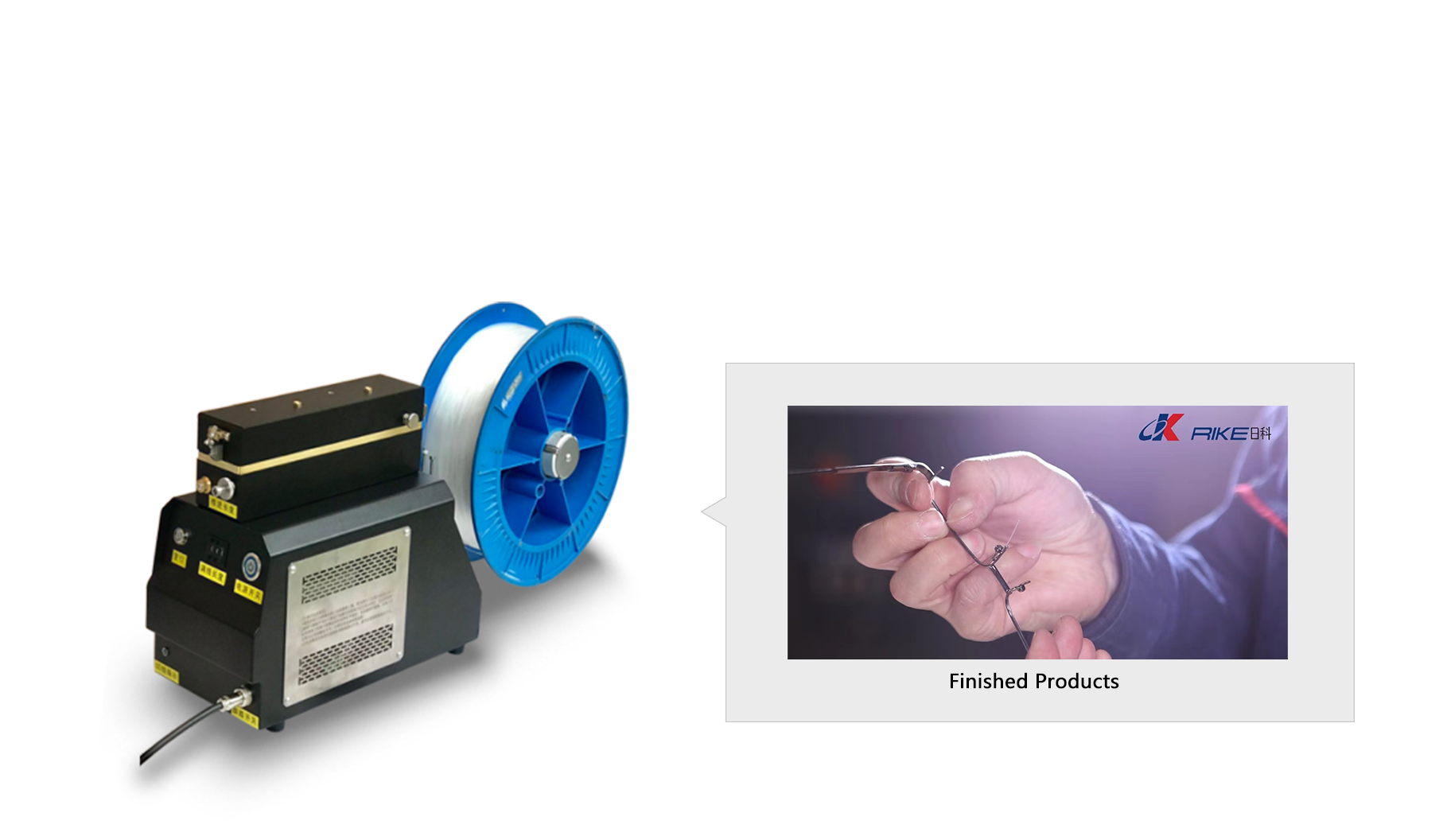

● Threading: Automated threading for metal semi-rim frames

● Process: This small-scale machine automates the threading process for metal semi-rim frames, significantly increasing efficiency. It can process up to 500 pieces per hour, ensuring a smooth and uniform finish without manual scratches.

Automation has revolutionized the eyewear manufacturing industry, enabling the production of both acetate and metal frames with unmatched precision, efficiency, and consistency. By utilizing advanced machines, manufacturers can produce high-quality eyewear while reducing labor costs and minimizing material waste, ultimately delivering superior products to the market.

As a leading eyewear automation machine manufacturer & production line solutions provider, we would be pleased to advise you individually, and you are also welcome to send your inquiry to [email protected].